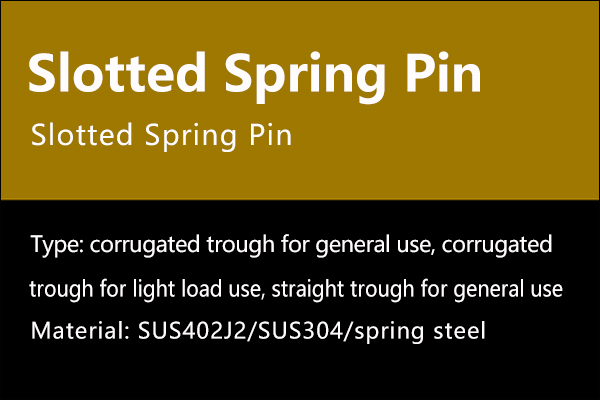

Spring Pin

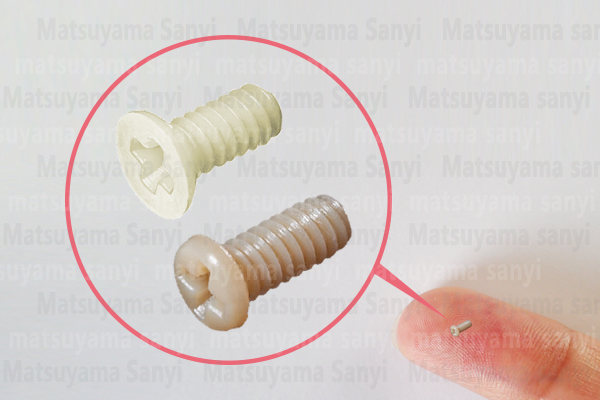

In addition to standard stock parts, we can also customize them, such as elastic cylindrical pins below Φ1

Characteristic

Generally used for corrugated grooves: SUS420J2, glossy surface, HRC42-48

Generally used for corrugated grooves: spring steel, quenching color, HRC45-53

Corrugated groove for light load: SUS304, glossy surface, HRC36-46

Straight groove is generally used: SUS420J2, glossy surface, HRC42-48

Generally used for straight grooves: spring steel, quenching color, HRC45-53

Characteristics of elastic cylindrical pins (Slotted Spring Pins)

1. A self-locking function occurs when a mating hole slightly smaller than the outer diameter of the spring pin is inserted.

2. Lighter than solid pins

3. There is no need for hole accuracy such as "fitting tolerance" between the shaft and the hole. It can be installed only by using the deformation of the spring pin.

4. When used in hinges of resin products, multiple functions can be used using the elasticity of the spring pin (positioning at any position + rotation, etc.)

5. Compared with the shaft, it is less likely to fall off due to vibration.

6. Double pins can also be used to increase shear force

Characteristics of elastic cylindrical pins (Slotted Spring Pins) produced by TAIYO

1. Both ends are chamfered to make them narrower and have good insertability. And not easy to get tangled together, suitable for automatic insertion

2. Materials, groove shapes, etc. can be selected according to the use occasion and purpose (stainless steel, spring steel. Corrugated groove, straight groove.)

3. It can also correspond to micro spring pins with an outer diameter of Φ1 or less.

4. Can recommend the best solution for rotation and sliding conditions

5. Double pins can also be assembled automatically (customized products)

6. Use the corrugation direction of the material to maximize the spring properties of the material.