CA/NN

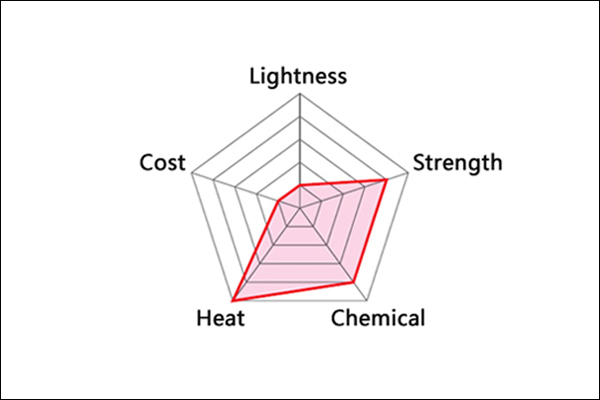

Ceramic (Alumina 96%) is widely used as general ceramics in large machinery parts and precision machinery parts due to its abrasion resistance, very high hardness and stable dimension.

In addition, it can be glued to metals with heat treatment. Also, it is widely used in semiconductor equipments due to excellent corrosion resistance and absence of out gas in high temperature gases.

Use RoHS2 compliant raw materials.

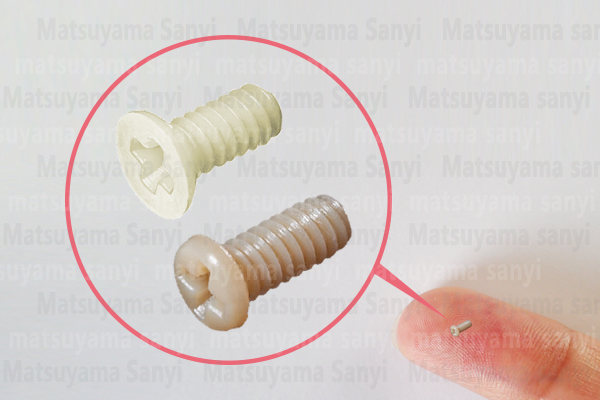

◆Gate residue of screw head is 5% or less for length (L).

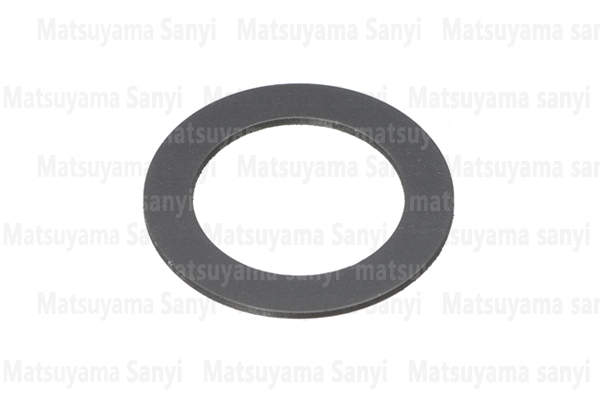

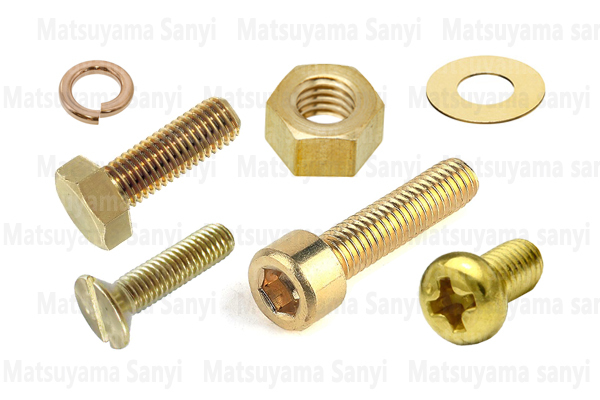

◆If screw is used with a nut, we recommend using the screw and nut made of the same material.

◆If screw is used with a female threaded part, we recommend maximum depth of 20 mm.

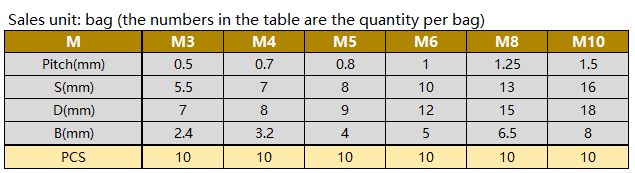

◆Values in the table are for reference purpose only, and they are not guaranteed values.

◆Please use torque driver or torque wrench for fastening. Recommended fastening torque is 50% of the torsional rupture torque.

◆Since heat resistance and chemical resistance change based on usage conditions, please test under actual usage conditions beforehand.

◆Discoloration may occur depending on lot and various conditions.

◆Sizes, shapes and manufacturers of raw materials may change without notice.