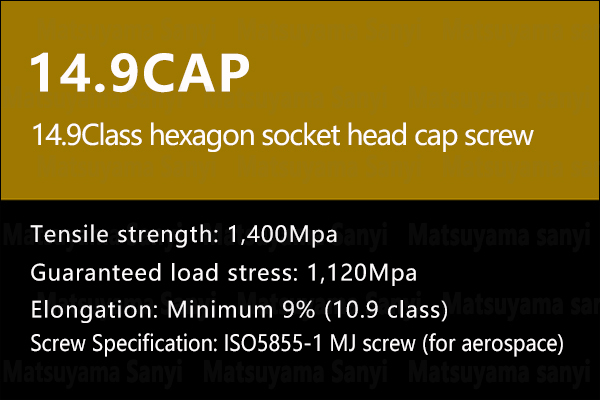

| Grade 14.9 high-strength hexagon socket head cap screw |

| developed by Kyokuto Seisakusho Co., Ltd., which has high technical capabilities |

| Tensile strength: 1,400Mpa |

| Guaranteed load stress: 1,120Mpa |

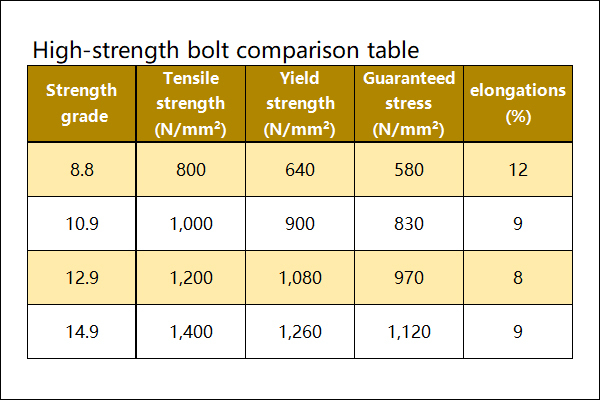

| High strength: Under the premise of ensuring the tensile strength of 1,400Mpa, the elongation rate of more than 9% can be achieved, and the same toughness of 10.9 grade can be achieved. |

| Anti-delayed fracture: Using KNDS4 steel from Kobelco, Japan, greatly improves the resistance to delayed fracture. |

| Fatigue resistance: [Aerospace MJ thread] is adopted to provide fatigue resistance. |

| High temperature resistance: 83% of the tensile strength can be maintained in an environment of 400 degrees. |

| Hardness: HRC44~50 |

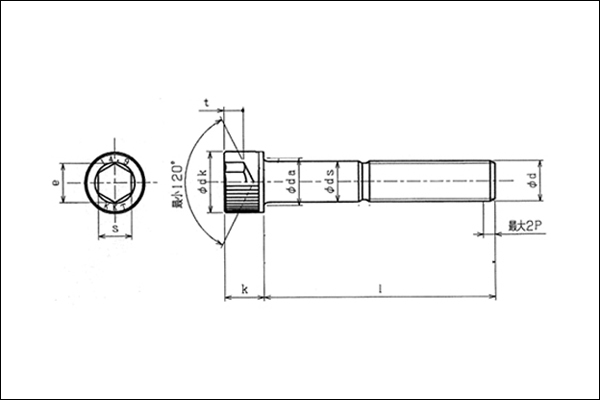

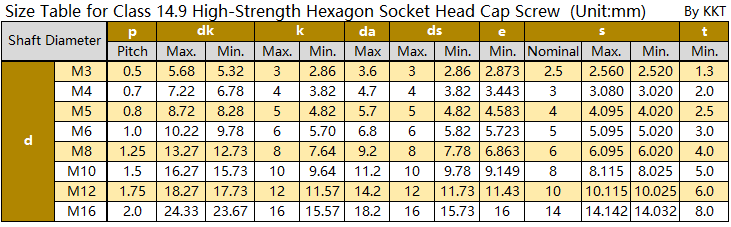

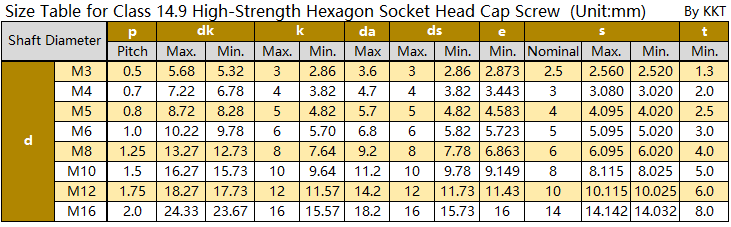

| Dimensions: JIS B1176 (except for the lower part of the neck) |

| Screw Specification: ISO5855-1 MJ screw (for aerospace) |

| Screw accuracy: ISO5955-1, 4 g6g |

| Surface treatment: Blackening and delta-protected coat (clear 1000 hours or longer in the salt spray test) |

12.9 CAP »

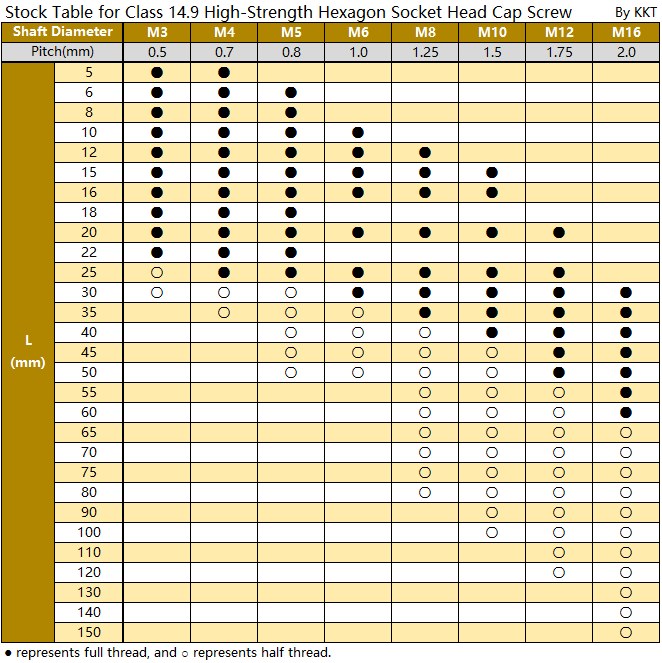

List of 「Product S1- CAP」